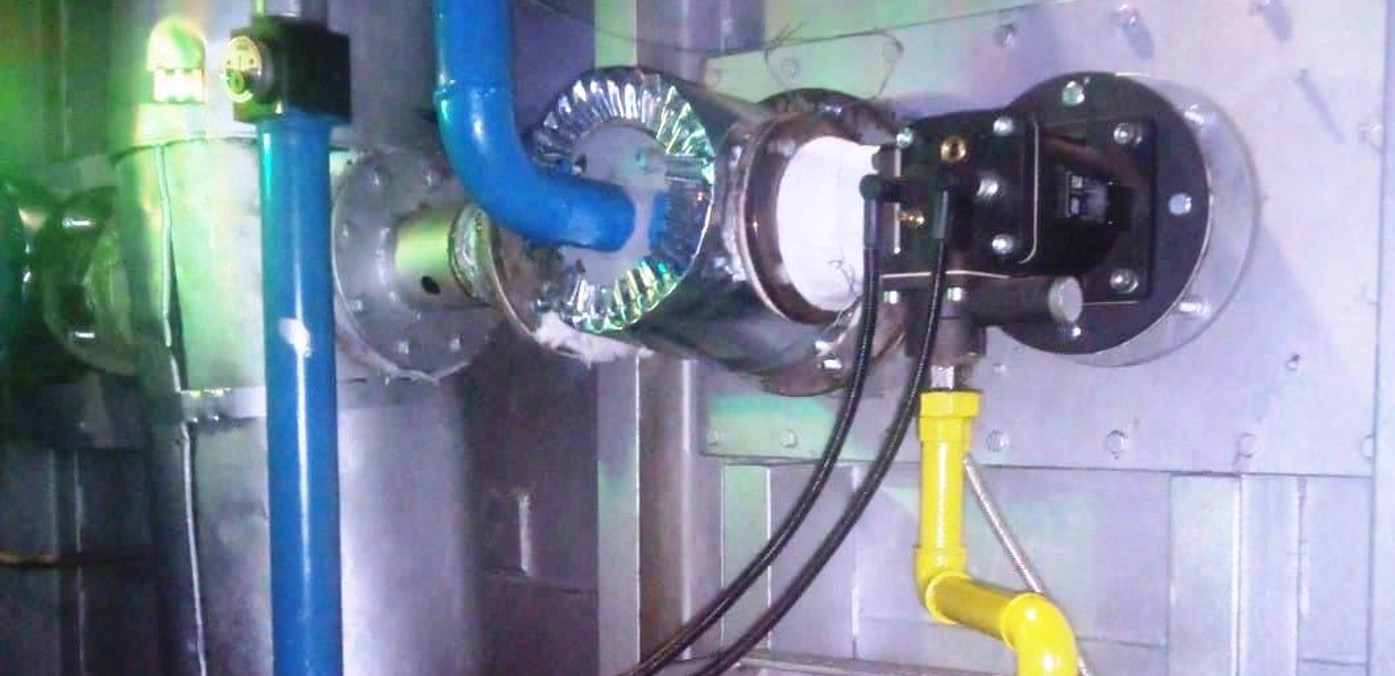

With this project, it is aimed to save energy by changing the combustion systems in the heating section of the annealing furnace that uses natural gas. Within the scope of the project, the type of combustion systems has been changed, air and natural gas lines have been replaced, separate temperature control has been provided for the heating zones, a new natural gas pressure reduction station has been installed, and insulation has been applied to the outer parts of combustion systems and heat recovery lines. After the project implementation, approximately 30% savings in natural gas consumption were achieved. The annual capacity of the line is 75,000 tons/year. As a part of the project, Erdemir Engineering has contributed to feasibility, planning, design, procurement, and project execution processes. The project was commissioned on April 12, 2022

| Design | SUPPLIER |

| Capacity | 75.000 Ton/Year |

| Strip Width | 500 - 1320 mm |

| Strip Thickness | 0,1 - 0,6 mm |

| Maximum Speed | 60 mpm |

| Project Duration | 1 Year(5 Months Design7 Months Execution) |

| Commissioning | April 2022 |

| Number of Contractor | 1 |

| Workforce | 40 Personnel 6 Designers |