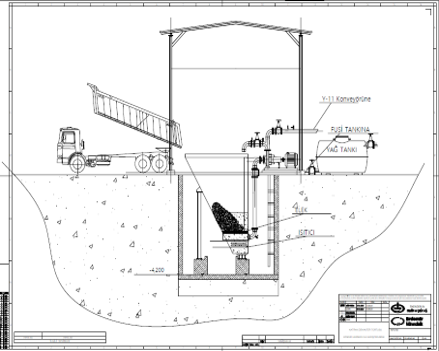

It was aimed to increase its contribution to production by designing a system to mix fusin, a by-product of coke production, with waste oil by heating it and feeding it to the coal transfer conveyor belt. This design is expected to yield approximately 144,000 USD per year. The work, which lasted 2 weeks within the scope of conceptual design, was completed in 2017.

| Objective | Ensuring effective disposal of tar pitch residue, which is produced as waste material in the coke production process, and bringing it into production. |

| Solution | The tar pitch will be mixed with the waste oils in the factory by heating and fluidized, and then added to the coal blend. |

| Tailored Approach | Approximately 200 tons per month of tar pitch residue, which is classified as hazardous waste and has high disposal costs, will be disposed of and brought into production. |

| Reference | No reference application. |