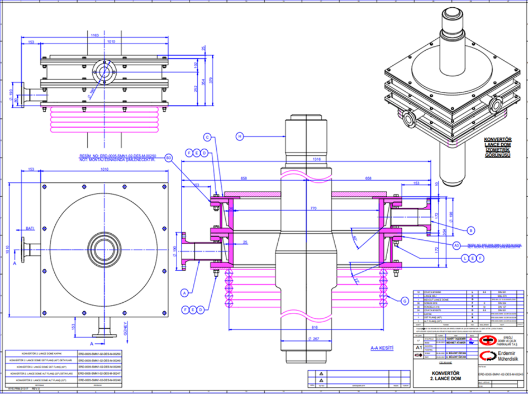

With this study, it is aimed to prevent the intense outflow of dust and gas in the converter process and to save the working environment from the effects of intense dust and gas. The nitrogen exit angles of the lower and upper layers of the collector are different. The emission that could pass through the first curtain was suppressed on the second floor and dust and gas were prevented from escaping. Within the scope of the study, it is anticipated that there will be an annual income of approximately 1,100,000 USD. Work within the scope of engineering and technical drawing took 12 months and was completed in 2023.

| Objective | During the converter process, intense gas and dust were leaking into the external environment. |

| Solution | A new design was made by changing the angle and position of the sealing blowing holes. 2-stage (layer) sealing design has been made |

| Tailored Approach | Reducing the need for cleaning by preventing collector sealing holes from forming scale, By reducing dust emissions, the need for environmental cleaning is reduced, It is ensured that the spread of process gas (mainly CO) in the nozzle dome area is prevented |

| Reference | Konvertor lance dome, 12 months (5 months design, 3 months manufacturing and 4 months installation), 2 Designers and 5 Person Application Team, Start Up– 2021-2022. |