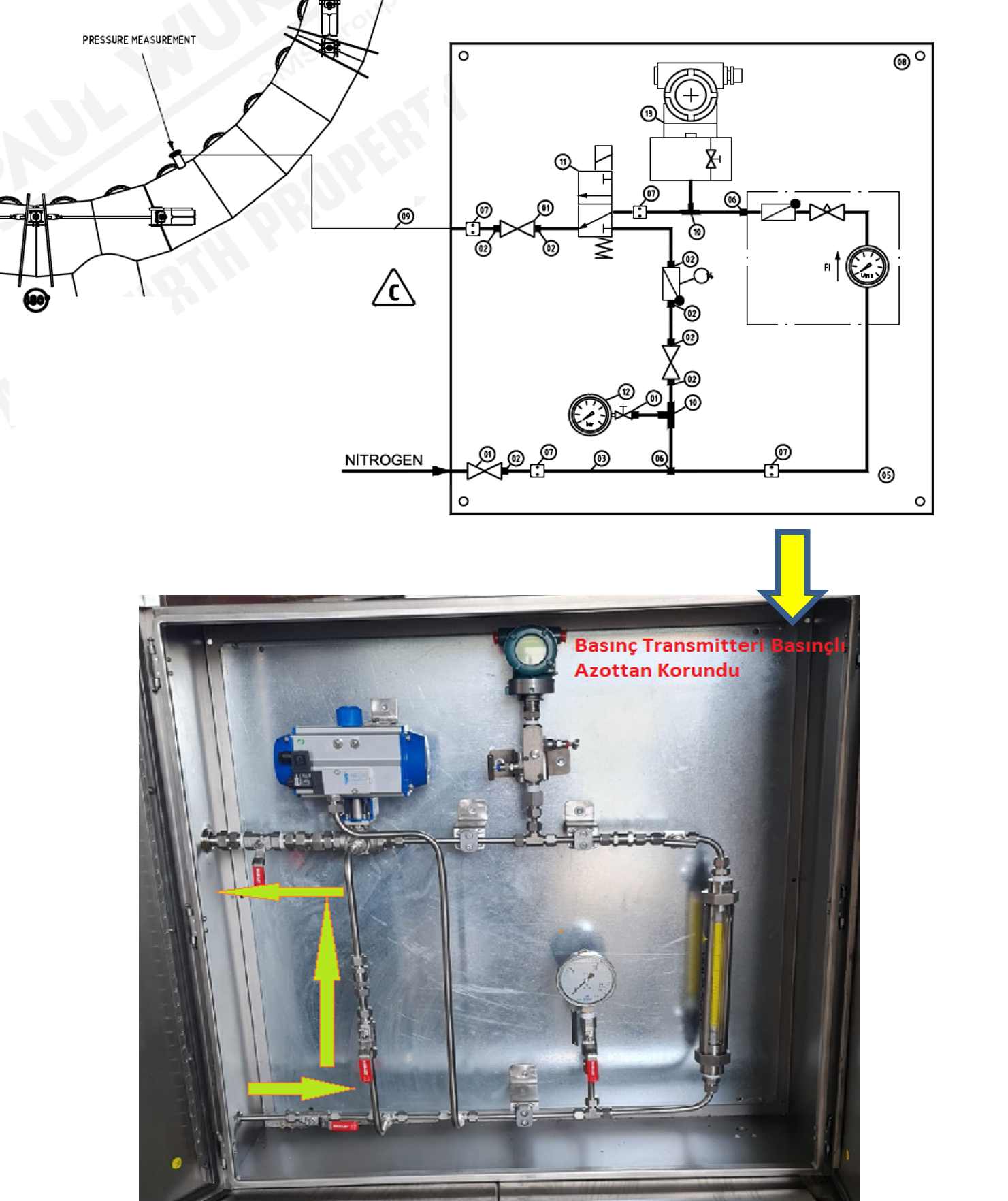

This study is about the pressure measurement device used to observe the internal furnace body pressures in the blast furnace process and the mechanism for cleaning this device. Thanks to this mechanism, in order to measure the pressure inside the dusty and hot blast furnace in a healthy way, the instrument is protected from the clogging problem caused by the dust coming from the measurement point and the effect of heat. In this way, it is aimed that the instrument can make continuous measurements without any errors and without requiring cleaning or maintenance. The subject mechanism is designed to be used not only in the Blast Furnace process but also in all pressurized closed vessels with dusty and hot processes. In addition, all lines between the process measurement point and the measurement device were mounted at an angle to prevent dirt from reaching the equipment where the device is located by gravity. Within the scope of the study, it is envisaged to generate approximately 15,000 Euros per year. Work within the scope of engineering and technical drawing was completed in 2023.

| Objective | Reducing unplanned downtime Reducing operating costs by reducing maintenance frequency. |

| Solution | Reducing the frequency of pressure transmitter maintenance by using a 3-way valve instead of a 2-way valve Oven internal pressure measurement. |

| Tailored Approach | Monitoring the inside furnace status and easy operation management with Internal Pressure measurement. |

| Reference | İsdemir New 1st Blast Furnace 14 months (4 months design, 9 months manufacturing and 1 month installation) 2 Designers and an 5 people Implementation Team Start Up– 2023 |