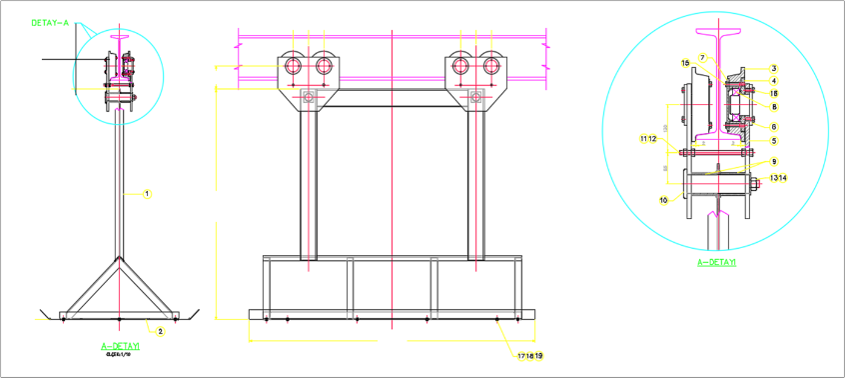

In the chromating section, zinc particles and dust carried on the strip surface fall on the bridle roll during the vertical movement of the strip, causing dent defects on on the strip. Particularly, periodic dent defects on the surface of B and C quality products may cause order deviation. A curtain has been designed to collect the zinc particles and dust that fall during the vertical movement of the strip before they reach to the bridle roll at the bottom. Work within the scope of concept, detail design and technical drawing took 3 months and was completed in 2022.

| Objective | To remove zinc particles and dusts carried on strip surface which fall on to the cooling roll sticking to the roll surface causing dents defects on strip surface, |

| Solution | A moveable curtain (tray) steel structure placed on top of the cooling roll unit to catch the falling zinc particles and dusts, Curtain (tray) steel structure connected to the maintenance monorail, |

| Tailored Approach | Elimination of Dent Defects on B & C Surface created by Cooling Roll Unit at Post Treatment Tower, Elimination of Downgrading due to Dent Defects, |

| Reference | ERDEMİR Continuous Galvanizin Line No.2, 3 months (1 month design + 2 mouths manufacture and implementation) Two designer and five person implemantation team, Commissioning – 2022 |