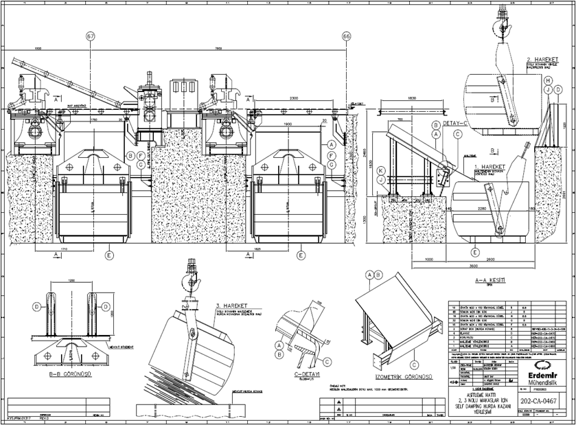

Scraps which are taken from entry pay of reels in Pickling Line No.2 are transported from scrap boxes to a container by hanging with steel ropes. This process has been performed in an unsuitable way and creating HSE risks. It has been ensured that, incoming scraps which come from shears of to pay off reels number 1 and 2, are directed, collected and unloaded by self-dumping method in accordance with suitable HSE rules. Work within the scope of concept, detail design and technical drawing took 2 months and was completed in 2019.

| Hedef | Eliminating the working difficulties in terms of OHS in the existing scrap disposal system Reducing crane and operator workload |

| Çözüm | Designing a new scrap box with higher carrying capacity and self-dumping feature |

| Müşteriye Özel | Providing a safe working condition in terms of OHS |

| Referans | Erdemir Continuous Pickling Line, 3 months (1 month design + 2 months manufacturing and implementation), Team: 3 Designers, 6-person Implementation Team, Commissioning – 2019. |